GEOSPATIAL INFORMATION SYSTEM

- Mapping My Journey

- Mapping My Journey

Geospatial Technology & Gas

Geographic Information System (GIS) is playing a pivotal role for utilities with applications for planning, designing, decision-making, network analysis and monitoring of environmental degradation. Use of this technology in gas distribution utilities has expanded tremendously in the last decade. GIS applications were built to model geospatial information and processes that support gas distribution utility network and operations in the real world.

GIS software companies have come up with solutions for different purpose such as Outage Management System, Engineering Design, Transmission Corridor Management, and Network Asset Management. Gas distribution companies have implemented these products separately to support their business workflows in various departments such as services groups, consumer groups, operations groups, billing groups, etc. The importance of common single workflow process phenomena across all departments has led to the conception of integrated GIS for gas distribution.

This paper presents details of GIS bearing on gas distribution system; concept of integrated GIS for gas distribution and how single-vendor based integrated GIS is evolving as a solution for a single workflow for a gas distribution company’s business processes.

Gas Distribution System

Gas distribution system is a connected pipeline system that carries natural gas from a source such as a city gate station or regulator station to the customer premises. A typical gas distribution system consists of assets such as main pipes and service pipes to distribute gas, valves, and regulator devices to control and regulate gas flow, joins and fittings to join different pipes and meters to measure inlet and outlet of gas. Gas transmission pipelines crossing state or country borders reach city borders and convert to gas distribution at city gate station. Gas is typically, regulated, odorized, filtered and measured at city gate station. Then gas may pass through several main pipelines to different localities within the city. Generally, service pipes connected to mains carry gas from mains to customer locations. Gas distribution system is complex, in contrast to gas and electric transmission systems, as it consists of many small segments of various diameter pipes joined by various types of fittings and gas control components placed at regular lengths of network. The pipes usually run up on one street and down on next, forming loops. What most distinguishes gas distribution from transmission is that distribution companies’ supply fuel to retail customers.

Therefore, gas utilities may like to manage inventory of their Gas distribution assets. They may be interested to know information such as particulars of gas leak locations and impact of environment on their assets. They may like to know what to put back into working order and what to replace. They may also like to know which of their assets impact other utilities, nearby to their own assets such as underground electric systems. Since gas distribution lines are underground, they must protect those lines from delinquent backhoe operators and people digging the ground for gardening.

Besides finding suitable site for new assets, losses in gas distribution and the growing concern over environmental issues are areas of concern that a gas utility must address. This requires the utility to accurately keep track of its assets in the field, such as asset location, size, status and spatial behavior. This task can be overwhelming for the utility without a GIS.

GIS for Gas Distribution System

Gas distribution companies are using GIS software products to support their engineering and operations functions and are realizing enhanced customer service, increased network reliability and reduced cost. GIS helps to maintain asset knowledge, which enables better use of available capacity such as size, pressure and inlet quantity of gas at station making it possible to use existing pipeline infrastructure before embarking on an expensive new build. With the recent advances in web-applications and adoption of broadband networks, it is now possible to integrate GIS with other business processes of the utility enterprise. For example, a work order that is raised for maintenance of an underground pipeline segment can have a link to online GIS map to locate not only the area of work, but also to get information such as depth at which the pipeline is buried, valves to be closed to isolate the maintenance region and details of other assets in the neighborhood.

Integrity Management in Gas Distribution

In the past, governments paid more attention to high pressure gas transmission pipeline integrity and wanted transmission companies to publish their integrity reports[2]. However, in recent times, American Gas Association (AGA), governments, pipeline safety regulators and many industry representatives have realized that integrity management has to be extended to the gas distribution networks too, considering their vicinity to living areas of people. Implementing integrity management enhances safety and also reduces risk to public property, improves gas distribution company’s asset life and builds up customer confidence.

In the future, integrity management for gas distribution system can become more formal. Just like transmission, issues can occur in gas distribution in the form of leaks, corrosion, excavation damages and unplanned outages. Gas distribution companies have to formulate programs to tackle integrity requirements. One prerequisite to integrity management is to understand the existing network elements such as mains, services, valves, regulators, cathodic sections, meters etc. This is easily achieved with the help of a GIS, which provides information about material used for piping, diameter, operating pressure, if the pipe is exposed or cased, leaks on pipes and their repair and maintenance history. This information helps in identifying threats to distribution system’s integrity that can be risky in the form of unpredictable damages to assets and people.

Leak Management:

A GIS can identify nearest valves or structures that need to be closed, to separate the leak area from rest of network to mitigate loss. After an accident or leak, the network has to be restored and damaged pipe segments have to be replaced. GIS applications can help in building the footage network that will replace failed network by identifying types of pipes (cast iron or steel), length of pipes and number of pipe segments. Leak analysis is another priority for integrity management. GIS interacts with leak database and discovers leak locations. A cluster analysis on leaks can be performed to determine the areas, which need immediate attention.

Risk Management

GIS can interact with pipe corrosion detection systems and show unprotected and exposed pipes in an area. If customer demand is expected to increase in that area, then gas distribution company can immediately make plans to replace the weak pipes or protect the vulnerable pipes to reduce risk of damage.

Safety:

Most of the times it is a regulation that requires reporting performance and health of the system. For example, under certain conditions of pressure, it is recommended[1] to have excess flow valve on a single line connection to reduce hazards and safeguard homes. GIS can maintain history of leaks on service lines and visually analyse this historical data to help make decisions about excess valve installations.

Apart from above, there are two most important areas to be assessed under distribution integrity. One is to supplement data for One Call Tickets to do risk analysis and provide to excavators and another is corrosion management to protect pipes.

One Call Analysis:

Many countries have mandated a regulation on making a telephone call to the “call before you dig” centre or one call centre, before doing any kind of excavation in order to avoid damages to utility networks, due to digging the ground. Based on the maps provided by utilities in proposed digging area, One call center determines if the excavator is digging in an unsafe area that can cause damage to gas or any other utility electrical lines and pipes buried under ground. The centre then notifies the gas or concerned utility by creating a one call ticket. It is now the gas (utility) company’s responsibility to provide full details on locations of their pipes that may be hit if excavation is done, and provide any other such instructions to carry out excavation without any damage by excavators. GIS plays a key role in this activity by directly locating the excavation area on map and displaying the pipeline details buried in that region. A full-scale report on these details can be produced from GIS that the gas (utility) company can submit to the one call center, which in turn instructs the excavators accordingly.

Corrosion Management:

For corrosion management, it is important to identify pipe segments that may need protection. The underground pipes, which are made of steel and iron other than plastic, corrode due to the proximity to earth. If a pipe segment is steel, it may require to be cathodically protected. GIS can be of great use for corrosion management as it can visually display the pipe segments covered by cathodic protection on the map and those that are not covered.

Integrated GIS

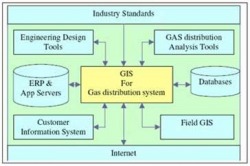

Due to the many advantages of using a GIS, Utilities are increasingly adopting GIS enabled solutions to meet their needs. A distinct trend towards deploying an Integrated GIS is being seen, by integrating the traditional GIS with other business applications such as engineering management tools, mobile workforce management system, outage management system, SCADA, and analysis tools.

An integrated GIS builds seamless interoperability among GIS and other systems to share data and services. Due to the growth in middleware technology, GIS vendors have come up with adaptors and connectors to middleware servers. This enables GIS to connect with multi-vendor supported enterprise systems, thus making GIS, a true enterprise application.

Integrated GIS for Gas Distribution System

If a new pipeline is to be laid, a design can be prepared in GIS by the engineering design department. It is also seen that there is a need to publish this design for review or approval or execution to different departments. During actual gas network layout, field engineers plan regular on-site inspections. A field engineer can view the gas network details in a GIS map on his personal digital assistant (PDA) and even enter comments, such as incorrect positioning of a fitting, or changed owner name of a gas meter. This has led to acceptance of web publishing technology for sharing data and publishing field data and the unremitting advancement of mobile platforms for field inspections.

Also, the growing need for a common workflow across various departments has led to integration of GIS system with in-house dedicated systems. GIS should integrate with operational support and service-delivery applications, enabling these systems to cooperate seamlessly in managing planning, design, construction, operations, maintenance, integrity, risk and emergency response functions of gas distribution and pipeline networks. GIS at enterprise level is required to provide geospatial data across the enterprise with full integration at all levels of systems and applications with full access to view and update data for a gas distribution system.

Additionally, there is a growing use of Internet GIS and industry standard platforms. Another such paradigm is component based programming, which provides state-of-art development environment for building custom applications for easy system extendability and custom-made capability of a modern GIS system. This increased the need for interoperability between prevalent systems.

Hence, requirement for integrated GIS solutions for gas distribution is on the rise. An integrated GIS empowers gas utilities to share information about mains, services, cathodic sections or one-call tickets of any size instantly and seamlessly across the enterprise. This helps in planning for safety system such as cathodic protection for new pipelines or helps in locating all the assets for a one-call ticket. Hence, an integrated GIS helps in fast decision-making, maintain health of the system, improve customer service and optimize business processes.

Challenges in Integrated GIS

A succinct life cycle of gas distribution network consists of following phases:

Challenges come in the following situations:

Single Vendor-based Integrated GIS is the future

A single vendor means a common data model and a common de facto standard for all individual systems. Upgrades and releases are done at the same time with out-of-box compatibility built within systems. Licenses can also be received in a single-go, thus reducing otherwise long waiting time for various systems. Some GIS vendors have realized the need for single vendor-based systems for enterprises. One such vendor is GE Energy, which recently released a product portfolio called Smallworld Office Suite* [4,5]. GE Energy’s office suite for gas utilities has products such as, Smallworld Gas Distribution Office*, Smallworld Global Transmission office*, Smallworld Design Manager* for engineering design, Smallworld Enterprise Application Integration (EAI) toolkit* for integration with legacy and other systems such as customer information systems and gas analysis systems. It has Smallworld Internet Application Server* (SIAS) to publish gas distribution network information and maps on Internet and intranet. It also consists of Smallworld Field Information System* that enables a field engineer to carry and update spatial information into the field.

Usage of a GIS for planning and operational purposes is increasing by the day in gas industry. Standards and specifications are continuing to evolve to achieve smooth interoperability between various GIS and non-GIS applications needed by the gas utilities. Based on the experiences of early adopters, a clear trend is being seen in the form of the gas utilities preferring an integrated GIS from a single vendor.

GIS software companies have come up with solutions for different purpose such as Outage Management System, Engineering Design, Transmission Corridor Management, and Network Asset Management. Gas distribution companies have implemented these products separately to support their business workflows in various departments such as services groups, consumer groups, operations groups, billing groups, etc. The importance of common single workflow process phenomena across all departments has led to the conception of integrated GIS for gas distribution.

This paper presents details of GIS bearing on gas distribution system; concept of integrated GIS for gas distribution and how single-vendor based integrated GIS is evolving as a solution for a single workflow for a gas distribution company’s business processes.

Gas Distribution System

Gas distribution system is a connected pipeline system that carries natural gas from a source such as a city gate station or regulator station to the customer premises. A typical gas distribution system consists of assets such as main pipes and service pipes to distribute gas, valves, and regulator devices to control and regulate gas flow, joins and fittings to join different pipes and meters to measure inlet and outlet of gas. Gas transmission pipelines crossing state or country borders reach city borders and convert to gas distribution at city gate station. Gas is typically, regulated, odorized, filtered and measured at city gate station. Then gas may pass through several main pipelines to different localities within the city. Generally, service pipes connected to mains carry gas from mains to customer locations. Gas distribution system is complex, in contrast to gas and electric transmission systems, as it consists of many small segments of various diameter pipes joined by various types of fittings and gas control components placed at regular lengths of network. The pipes usually run up on one street and down on next, forming loops. What most distinguishes gas distribution from transmission is that distribution companies’ supply fuel to retail customers.

Therefore, gas utilities may like to manage inventory of their Gas distribution assets. They may be interested to know information such as particulars of gas leak locations and impact of environment on their assets. They may like to know what to put back into working order and what to replace. They may also like to know which of their assets impact other utilities, nearby to their own assets such as underground electric systems. Since gas distribution lines are underground, they must protect those lines from delinquent backhoe operators and people digging the ground for gardening.

Besides finding suitable site for new assets, losses in gas distribution and the growing concern over environmental issues are areas of concern that a gas utility must address. This requires the utility to accurately keep track of its assets in the field, such as asset location, size, status and spatial behavior. This task can be overwhelming for the utility without a GIS.

GIS for Gas Distribution System

Gas distribution companies are using GIS software products to support their engineering and operations functions and are realizing enhanced customer service, increased network reliability and reduced cost. GIS helps to maintain asset knowledge, which enables better use of available capacity such as size, pressure and inlet quantity of gas at station making it possible to use existing pipeline infrastructure before embarking on an expensive new build. With the recent advances in web-applications and adoption of broadband networks, it is now possible to integrate GIS with other business processes of the utility enterprise. For example, a work order that is raised for maintenance of an underground pipeline segment can have a link to online GIS map to locate not only the area of work, but also to get information such as depth at which the pipeline is buried, valves to be closed to isolate the maintenance region and details of other assets in the neighborhood.

Integrity Management in Gas Distribution

In the past, governments paid more attention to high pressure gas transmission pipeline integrity and wanted transmission companies to publish their integrity reports[2]. However, in recent times, American Gas Association (AGA), governments, pipeline safety regulators and many industry representatives have realized that integrity management has to be extended to the gas distribution networks too, considering their vicinity to living areas of people. Implementing integrity management enhances safety and also reduces risk to public property, improves gas distribution company’s asset life and builds up customer confidence.

In the future, integrity management for gas distribution system can become more formal. Just like transmission, issues can occur in gas distribution in the form of leaks, corrosion, excavation damages and unplanned outages. Gas distribution companies have to formulate programs to tackle integrity requirements. One prerequisite to integrity management is to understand the existing network elements such as mains, services, valves, regulators, cathodic sections, meters etc. This is easily achieved with the help of a GIS, which provides information about material used for piping, diameter, operating pressure, if the pipe is exposed or cased, leaks on pipes and their repair and maintenance history. This information helps in identifying threats to distribution system’s integrity that can be risky in the form of unpredictable damages to assets and people.

Leak Management:

A GIS can identify nearest valves or structures that need to be closed, to separate the leak area from rest of network to mitigate loss. After an accident or leak, the network has to be restored and damaged pipe segments have to be replaced. GIS applications can help in building the footage network that will replace failed network by identifying types of pipes (cast iron or steel), length of pipes and number of pipe segments. Leak analysis is another priority for integrity management. GIS interacts with leak database and discovers leak locations. A cluster analysis on leaks can be performed to determine the areas, which need immediate attention.

Risk Management

GIS can interact with pipe corrosion detection systems and show unprotected and exposed pipes in an area. If customer demand is expected to increase in that area, then gas distribution company can immediately make plans to replace the weak pipes or protect the vulnerable pipes to reduce risk of damage.

Safety:

Most of the times it is a regulation that requires reporting performance and health of the system. For example, under certain conditions of pressure, it is recommended[1] to have excess flow valve on a single line connection to reduce hazards and safeguard homes. GIS can maintain history of leaks on service lines and visually analyse this historical data to help make decisions about excess valve installations.

Apart from above, there are two most important areas to be assessed under distribution integrity. One is to supplement data for One Call Tickets to do risk analysis and provide to excavators and another is corrosion management to protect pipes.

One Call Analysis:

Many countries have mandated a regulation on making a telephone call to the “call before you dig” centre or one call centre, before doing any kind of excavation in order to avoid damages to utility networks, due to digging the ground. Based on the maps provided by utilities in proposed digging area, One call center determines if the excavator is digging in an unsafe area that can cause damage to gas or any other utility electrical lines and pipes buried under ground. The centre then notifies the gas or concerned utility by creating a one call ticket. It is now the gas (utility) company’s responsibility to provide full details on locations of their pipes that may be hit if excavation is done, and provide any other such instructions to carry out excavation without any damage by excavators. GIS plays a key role in this activity by directly locating the excavation area on map and displaying the pipeline details buried in that region. A full-scale report on these details can be produced from GIS that the gas (utility) company can submit to the one call center, which in turn instructs the excavators accordingly.

Corrosion Management:

For corrosion management, it is important to identify pipe segments that may need protection. The underground pipes, which are made of steel and iron other than plastic, corrode due to the proximity to earth. If a pipe segment is steel, it may require to be cathodically protected. GIS can be of great use for corrosion management as it can visually display the pipe segments covered by cathodic protection on the map and those that are not covered.

Integrated GIS

Due to the many advantages of using a GIS, Utilities are increasingly adopting GIS enabled solutions to meet their needs. A distinct trend towards deploying an Integrated GIS is being seen, by integrating the traditional GIS with other business applications such as engineering management tools, mobile workforce management system, outage management system, SCADA, and analysis tools.

An integrated GIS builds seamless interoperability among GIS and other systems to share data and services. Due to the growth in middleware technology, GIS vendors have come up with adaptors and connectors to middleware servers. This enables GIS to connect with multi-vendor supported enterprise systems, thus making GIS, a true enterprise application.

Integrated GIS for Gas Distribution System

If a new pipeline is to be laid, a design can be prepared in GIS by the engineering design department. It is also seen that there is a need to publish this design for review or approval or execution to different departments. During actual gas network layout, field engineers plan regular on-site inspections. A field engineer can view the gas network details in a GIS map on his personal digital assistant (PDA) and even enter comments, such as incorrect positioning of a fitting, or changed owner name of a gas meter. This has led to acceptance of web publishing technology for sharing data and publishing field data and the unremitting advancement of mobile platforms for field inspections.

Also, the growing need for a common workflow across various departments has led to integration of GIS system with in-house dedicated systems. GIS should integrate with operational support and service-delivery applications, enabling these systems to cooperate seamlessly in managing planning, design, construction, operations, maintenance, integrity, risk and emergency response functions of gas distribution and pipeline networks. GIS at enterprise level is required to provide geospatial data across the enterprise with full integration at all levels of systems and applications with full access to view and update data for a gas distribution system.

Additionally, there is a growing use of Internet GIS and industry standard platforms. Another such paradigm is component based programming, which provides state-of-art development environment for building custom applications for easy system extendability and custom-made capability of a modern GIS system. This increased the need for interoperability between prevalent systems.

Hence, requirement for integrated GIS solutions for gas distribution is on the rise. An integrated GIS empowers gas utilities to share information about mains, services, cathodic sections or one-call tickets of any size instantly and seamlessly across the enterprise. This helps in planning for safety system such as cathodic protection for new pipelines or helps in locating all the assets for a one-call ticket. Hence, an integrated GIS helps in fast decision-making, maintain health of the system, improve customer service and optimize business processes.

Challenges in Integrated GIS

A succinct life cycle of gas distribution network consists of following phases:

- Planning gas network with regulation stations, mains, services, valves etc.

- Creating an engineering design for the network, based on

1. Best cost model

2. Available material through enterprise resource planning (ERP) system - Performing analysis on proposed and existing networks for optimization

- Approving engineering designs

- Procuring material

- Field inspections during network construction

- Energizing the as-built network

- Service provisioning

- Asset management

- Gas outage management

- Operations and maintenance

- Leak analysis

- Cathodic protection

Challenges come in the following situations:

- Building a common data model across all products and applications

- What common standards to be followed

- Coordination between various departments

- Lead time for licenses can be longer as it amounts to the last license delivered

- New installations/upgrades for individual systems is cumulative

Single Vendor-based Integrated GIS is the future

A single vendor means a common data model and a common de facto standard for all individual systems. Upgrades and releases are done at the same time with out-of-box compatibility built within systems. Licenses can also be received in a single-go, thus reducing otherwise long waiting time for various systems. Some GIS vendors have realized the need for single vendor-based systems for enterprises. One such vendor is GE Energy, which recently released a product portfolio called Smallworld Office Suite* [4,5]. GE Energy’s office suite for gas utilities has products such as, Smallworld Gas Distribution Office*, Smallworld Global Transmission office*, Smallworld Design Manager* for engineering design, Smallworld Enterprise Application Integration (EAI) toolkit* for integration with legacy and other systems such as customer information systems and gas analysis systems. It has Smallworld Internet Application Server* (SIAS) to publish gas distribution network information and maps on Internet and intranet. It also consists of Smallworld Field Information System* that enables a field engineer to carry and update spatial information into the field.

Usage of a GIS for planning and operational purposes is increasing by the day in gas industry. Standards and specifications are continuing to evolve to achieve smooth interoperability between various GIS and non-GIS applications needed by the gas utilities. Based on the experiences of early adopters, a clear trend is being seen in the form of the gas utilities preferring an integrated GIS from a single vendor.